Will networked 3D printing be the next big thing?

3D NEWS> 3D PRINTING

3D Hubs isn’t like any other social network explains Andrew Walker

It’s a manufacturing network that’s distributed within communities around the world. It’s mashing-up the real world need for industrial production with the digital networks and individuals that share them, like Facebook for products. That means anyone can connect their home 3D printer to 3D Hubs, transforming it into a local node on a global distributed manufacturing facility… it is, quite literally, making money.

Imagine the scene. You get home from work to find a plastic plumbing widget cooling on your printer bed. You get an email from someone you’ve never met, paying you to deliver it a few streets away for them. They’re emailing from Japan, you’re in Edinburgh. They’ve just saved money on international shipping and you’ve made money from the 3D printer that used to do nothing all day whilst you were at work. It sounds like the opening scene of a new sci-fi detective show, but it’s not. It’s one possible future for global mass production that might transform the global manufacturing economy and with it, society. That’s what 3D Hubs founders Bram de Zwart and Brian Garret are aiming for.

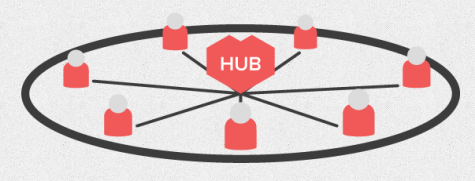

The idea is simple. Network together 3D printers through a web interface. Get users to register their printer availability with a map pin, so users can find their nearest one. Then people can select a hub, near where they want to send an object, and ask a local Hubber to 3D print and deliver it. In theory that’s easy, it’s got a few speed-bumps to smooth out, but given time and better interoperability in the way OEM 3D printer drivers process objects, it could become easy, even to your granny.

The idea is simple. Network together 3D printers through a web interface. Get users to register their printer availability with a map pin, so users can find their nearest one. Then people can select a hub, near where they want to send an object, and ask a local Hubber to 3D print and deliver it. In theory that’s easy, it’s got a few speed-bumps to smooth out, but given time and better interoperability in the way OEM 3D printer drivers process objects, it could become easy, even to your granny.

Okay, right now your gran might use Facebook, but finding, downloading and remotely printing a 3D model in the right format for a Makerbot to produce remotely via 3D Hubs is a bit much to expect. Nevertheless, the social and commercial opportunities that drive 3D Hub’s value proposition are compelling, they could become serious contender for the title of “next big thing” or more likely the next “next big thing” after that.

3D Hub’s model doesn’t just offer individuals participation in a distributed manufacturing network, the commercial applications are very wide too. Your local DIY store could be a hub and sell on-demand plastic widgets, produced via them from the customer service helpline for your broken washing machine. Your local doctor’s surgery hub could distribute medication in personalised packaging, extremely useful for complex medication like cancer treatments, sent via them from your hospital specialist. Your car manufacturer can send you replacement parts via your 3D Hub neighbour at a fraction of the cost of keeping them in a warehouse and shipping them to you. On-demand network services have been applied to retail, CRM, logistics, public services, entertainment, travel, passports, law enforcement, farming, shipping, education… why not manufacturing?

It may be a little naive to suggest Volkswagen will be shipping replacement parts via random local 3D Hubbers, but the principle is sound, it’s just an evolution of the way global brands already produce products locally. That’s why it’s so compelling. In the same way Facebook turbocharged our ability to use cyberspace as a communications and publishing platform (that's what 'friending' and uploading your holiday snaps is) 3D Hubs enables the manufacture and distribution of physical objects in a way that’s scalable and truly global. It’s also cheaper because cutting out unnecessary middle-man links in a supply chain reduces costs at both ends. It’s ‘disintermediation’ – the jargon that describes what happened to big record labels and travel agents when we started bypassing their monopoly on sales and distribution with direct sales into our iPods and PCs.

If it takes off we’re also moving towards ‘zerowaste’ production – making the stuff we need locally, only when we need it. Zerowaste reduces packaging, CO2 emissions, freight traffic, storage costs and increases the value of recycled raw materials. That changes the economic goalposts for manufacturing and creates unpredictable market forces for oil, paper and plastics, potentially growing new sectors within the global economy. That’s good considering many old sectors of the economy are either flatlining (in Europe and the US) or subject to social unrest and spiralling costs in emerging markets (Asia, Africa and South America).

There’s something more humane in the 3D Hubs proposition. If manufacturing becomes distributed throughout communities, the wealth of global business will be distributed along with it. That’s social enterprise, redistributing some of the wealth concentrated in corporate bank accounts directly into communities through micro-payments. Put simply, for company A, the big spend with manufacturer B and shipping company C turns into a tiny spend with thousands of ordinary people for low-volume, local production. It’s an intriguing idea, potentially addressing the systemic causes of poverty through manufacturing GDP rather than taxpayer-funded aid, education or charity work.

If the idea of plumbing fixtures or gear knobs being produced under the stairs in a council house in Manchester, or under the bed in Soweto sounds crazy, consider that thirty years ago the prospect of a supermarket selling cheap laser printers would have sounded twice as crazy. Twenty years ago the idea of buying groceries online would have got you laughed out of college (that’s how I ended my postgrad, actually) and just over five years ago the CEO of Microsoft almost wet his pants with laughter on at the mere rumour of a $500 mobile phone from Apple. I wonder how hard he laughed when the AppStore made its first billion?

I interviewed Brian and Bram at the opening party for the iMakr store in London. They’re taking their time before they seek investment – but there is already a lot of interest from angels and VCs. 3D Hubs is ripe for investment, combining a simple proposition at the bleeding edge of new hardware with a dream somewhere between a geeky Utopia and Tim Berners Lee. One day, they envision a world of subscription-based digital production or as Brian calls it “Spotify for products”. Bram simply smiles and says “Everyone is a manufacturer”. They’re starting small, light on infrastructure and have a long way to go before 3D Hubs changes the world, but then again… isn’t that how Facebook started?

Andrew Walker is a Chief Plastician and runs the blog UniquePlastique.com. Follow him at @uniqueplastique.

FREE WEEKLY 3D NEWS BULLETIN –